UV Pressurized Curing Device “Type: MLP-320G”

Product Details

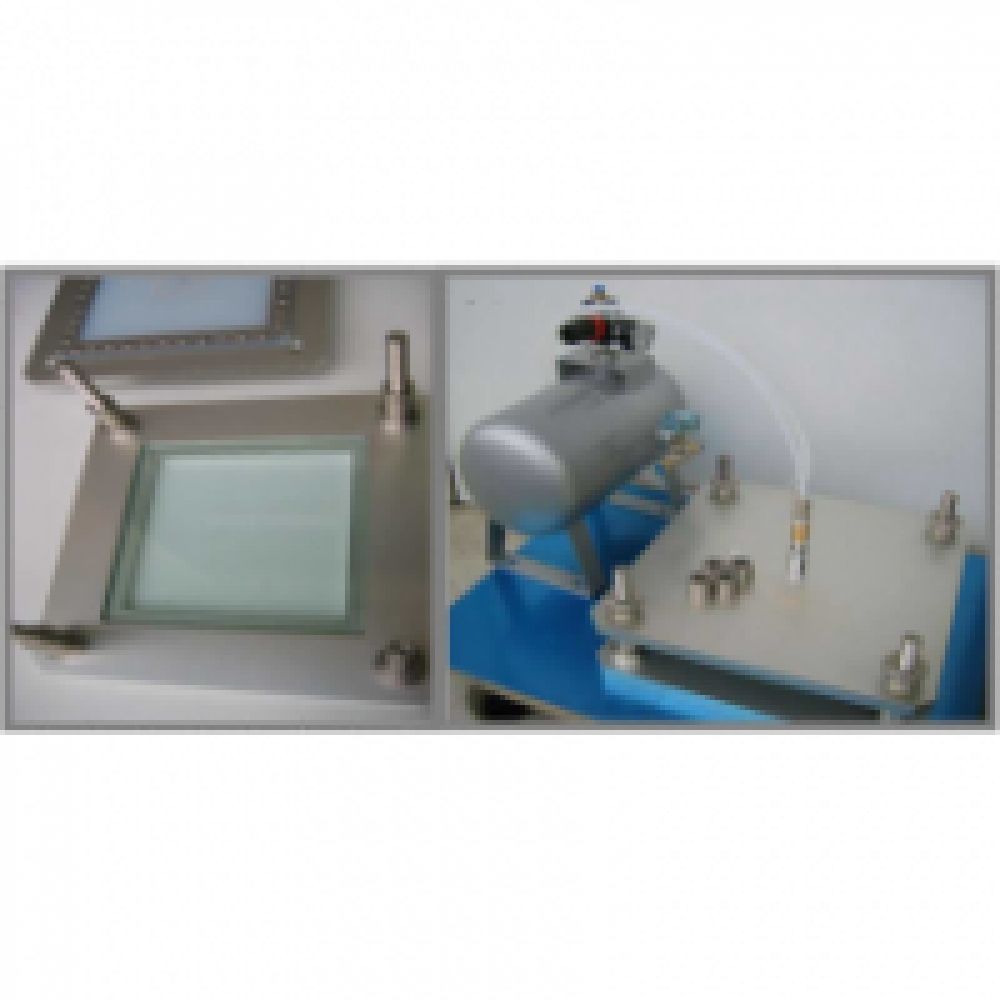

A pressurized curing device for experiments capable of UV curing after pressurizing with gap control still in effect.

The UV Pressurized Curing Device “Type: MLP-320G” is a tabletop, general-purpose device that pressurizes and UV cures glass panes up to a maximum of 150mm × 150mm in size.

Its pressurizer, made from silicon rubber, applies uniform pressure on test pieces.

Various types of UV-irradiated glass are selectable, including quartz glass with excellent permeability.

[Composition]

○Pressurized plate vertical set and three types of gap adjusting collars

○Air tank (regulator and needle valve included)

○Air connection coupler, Teflon tube (2m)

Product Specifications

○Pressurization gap adjustment: Enables gap dimension adjustment using SUS collar combination

○Heat-resistance: Up to approx. 150℃

○Spacers: Exchangeable 10mm, 20mm, 30mm SUS collars

○Test piece glass size: 150mm × 150mm (Max.) × 0.3~2mmt

○Utilities: Compressed air connected to regulator via plant supply port

○External dimensions: 320mm wide × 320mm long × 100mm tall

*May vary depending on specifications.